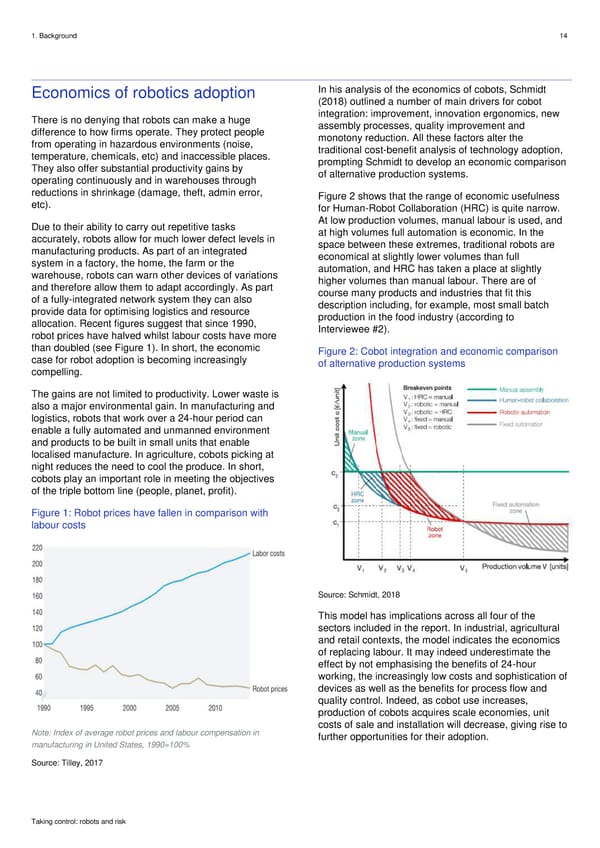

1. Background 14 Economics of robotics adoption In his analysis of the economics of cobots, Schmidt (2018) outlined a number of main drivers for cobot There is no denying that robots can make a huge integration: improvement, innovation ergonomics, new difference to how firms operate. They protect people assembly processes, quality improvement and from operating in hazardous environments (noise, monotony reduction. All these factors alter the temperature, chemicals, etc) and inaccessible places. traditional cost-benefit analysis of technology adoption, They also offer substantial productivity gains by prompting Schmidt to develop an economic comparison operating continuously and in warehouses through of alternative production systems. reductions in shrinkage (damage, theft, admin error, Figure 2 shows that the range of economic usefulness etc). for Human-Robot Collaboration (HRC) is quite narrow. Due to their ability to carry out repetitive tasks At low production volumes, manual labour is used, and accurately, robots allow for much lower defect levels in at high volumes full automation is economic. In the manufacturing products. As part of an integrated space between these extremes, traditional robots are system in a factory, the home, the farm or the economical at slightly lower volumes than full warehouse, robots can warn other devices of variations automation, and HRC has taken a place at slightly and therefore allow them to adapt accordingly. As part higher volumes than manual labour. There are of of a fully-integrated network system they can also course many products and industries that fit this provide data for optimising logistics and resource description including, for example, most small batch allocation. Recent figures suggest that since 1990, production in the food industry (according to robot prices have halved whilst labour costs have more Interviewee #2). than doubled (see Figure 1). In short, the economic Figure 2: Cobot integration and economic comparison case for robot adoption is becoming increasingly of alternative production systems compelling. The gains are not limited to productivity. Lower waste is also a major environmental gain. In manufacturing and logistics, robots that work over a 24-hour period can enable a fully automated and unmanned environment and products to be built in small units that enable localised manufacture. In agriculture, cobots picking at night reduces the need to cool the produce. In short, cobots play an important role in meeting the objectives of the triple bottom line (people, planet, profit). Figure 1: Robot prices have fallen in comparison with labour costs Source: Schmidt, 2018 This model has implications across all four of the sectors included in the report. In industrial, agricultural and retail contexts, the model indicates the economics of replacing labour. It may indeed underestimate the effect by not emphasising the benefits of 24-hour working, the increasingly low costs and sophistication of devices as well as the benefits for process flow and quality control. Indeed, as cobot use increases, production of cobots acquires scale economies, unit Note: Index of average robot prices and labour compensation in costs of sale and installation will decrease, giving rise to manufacturing in United States, 1990=100% further opportunities for their adoption. Source: Tilley, 2017 Taking control: robots and risk

Robots & Risk Page 13 Page 15

Robots & Risk Page 13 Page 15